Thordon is a pioneer in the design and development of pollution-free open bearing systems which provide an excellent alternative to oil-based systems, since leakage risks are eliminated and maintenance is reduced.

We have all the certificates from different classification bodies.

Benefits:

We have different grades of bearing depending on the type of boat. We choose the one that is most appropriate, taking into account the work to be done and the type of water in which the boat will sail, so that it lasts as long as possible.

We produce mechanical seals with high abrasion resistance. Their unique emergency seal allows you to continue sailing when it is activated.

We have a cyclonic filter to eliminate seawater abrasion and send clean water to the stern tube and to the face seal.

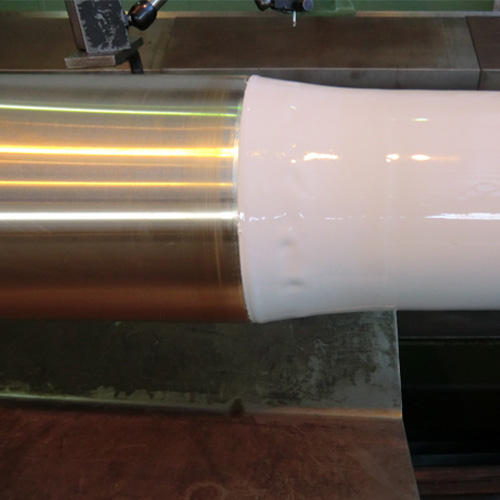

Coating to protect the shaft against corrosion. It has exceptional flexibility and high strength and hardness.

Different designs of cutters to protect against possible entanglement with ropes, nets and seaweed. Spurs cutters are made with the best materials.

KIWI floating shaft seals are designed to offer the best protection for your boat.

Composite stern tubes. These are not affected by corrosion and are ideal for mounting with our Thordon bearings and KIWI shaft seals.

Provision of the complete Thordon system (Thordon Composite Bearings, Water Quality package, TG-100 Seal, etc.) for the construction in the Armon Shipyards of the fishing vessel “Lady Comeau III” for the shipowner Comeau’s Sea foods Ltd.

This has the seawater-lubricated Thordon COMPAC system installed on the tail shaft (consisting of COMPAC stern and bow bearing installed by means of a fixed key and the WQP filtration and lubrication system, with MON-SHAFT certification).