The segmented seal of the main shaft of a turbine normally operates with exposure to high PV conditions and also to abrasive water. For this reason, the Thordon SXL seal is a benchmark solution for working in both clean and abrasive water.

Main characteristics:

Although Thordon SXL seals can be replaced directly by carbon or phenolic seals with the same design, it is advisable to review the particular application with us.

To be reviewed:

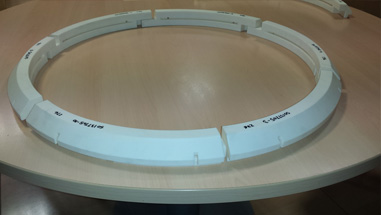

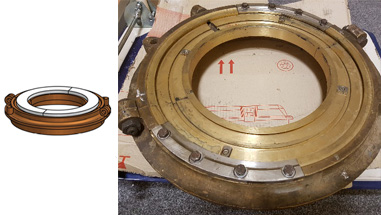

The SXL radial segmented seal is usually composed of between 1 and 3 rings, depending on the turbine water pressure. Each ring creates both a dynamic seal (against the shaft sleeve) and a static seal (against the housing).

The SXL axial segmented seal works in a similar way to conventional mechanical seals. Water is injected into the central groove for lubrication. The segments are normally installed in the stationary area of the turbine.

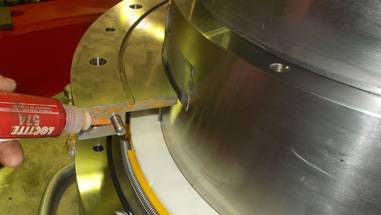

Design and replacement of the existing carbon seals of the turbines of the San Pedro plant, belonging to Iberdrola, with our Thordon radial seal design.

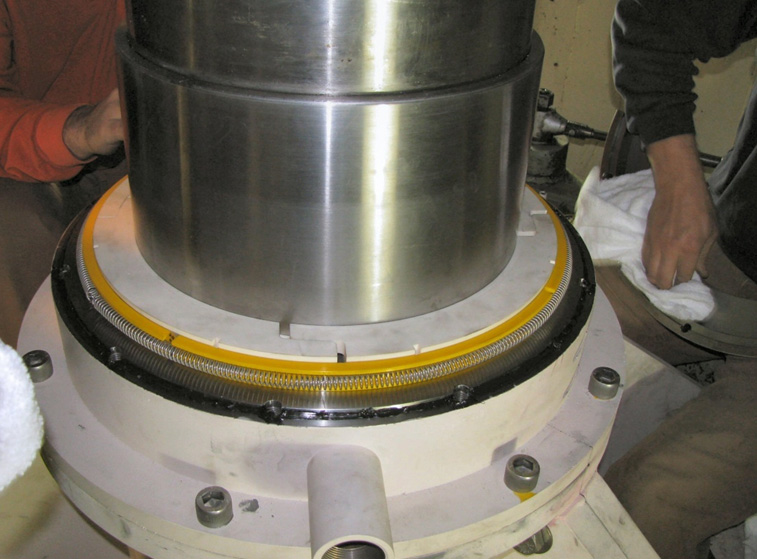

Thordon radial segmented seals were designed and manufactured as part of the conversion design for the main guide shaft bearing system of the two units of the Prada hydroelectric power plant belonging to ENEL. They consist of two rings composed of seals in Thordon SXL material, a pressure ring in conventional material, and a spring to tighten the whole assembly against the shaft, and are installed in the upper part of the guide bearing so that they can be accessed quickly and easily in case preventive maintenance is required.

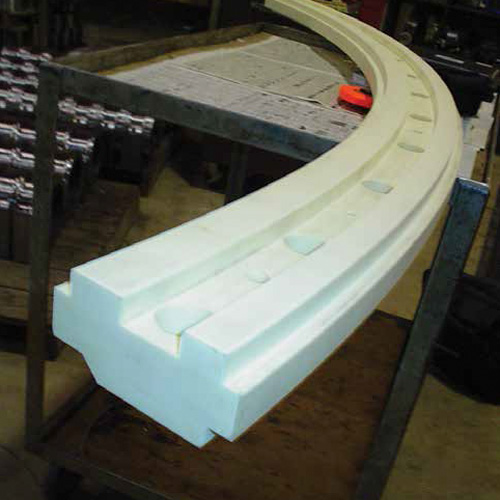

Replacement of the axial carbon seal with a design that was moulded to fit the existing housing using our Thordon SXL material in the Argone plant belonging to Acciona. In this case, the part manufactured in our material was designed so that the seal could be moulded without the need to modify the seal housing at all.

The San Martín plant is located in the River Sil and belongs to Iberdrola. It has a turbine in which the carbon seals had to be changed very regularly, and a solution was designed using our Thordon seal so that the carbon seal could be replaced without the need to modify the housing in any way, which meant a problem-free replacement of the seal. Since installation, it has been running smoothly for several years, far surpassing the life of the carbon seal.