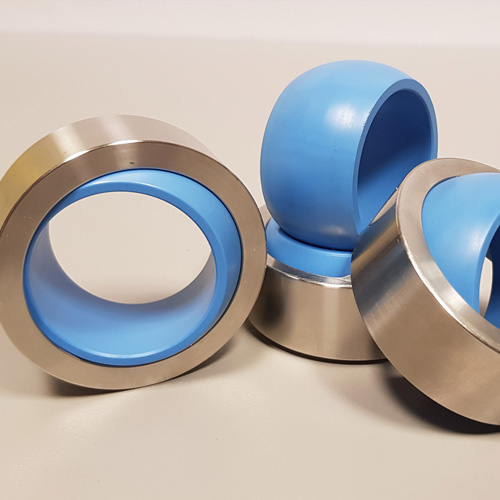

Thordon is an elastomeric material made of thermosetting resins which are polymers with three-dimensionally interwoven structures. Thordon is a very hard and resistant synthetic polymer alloy with performance characteristics which are superior to other materials used for metallic and non-metallic bearings.

Compared to other materials, Thordon works particularly well in applications where the material is exposed to or submerged in water, especially in extremely dirty conditions, and where shock forces are an important factor.

There are two basic reasons for Thordon’s superior behaviour: First, Thordon is an elastomer and so it returns to its original form after being compressed or deformed under normal operating conditions; and second, due to the basic characteristics of the material, Thordon has a high resistance to abrasion. These two characteristics lead to exceptional performance and long life in many difficult environmental conditions, or where there is considerable dirt, both in maritime, industrial and energy applications.

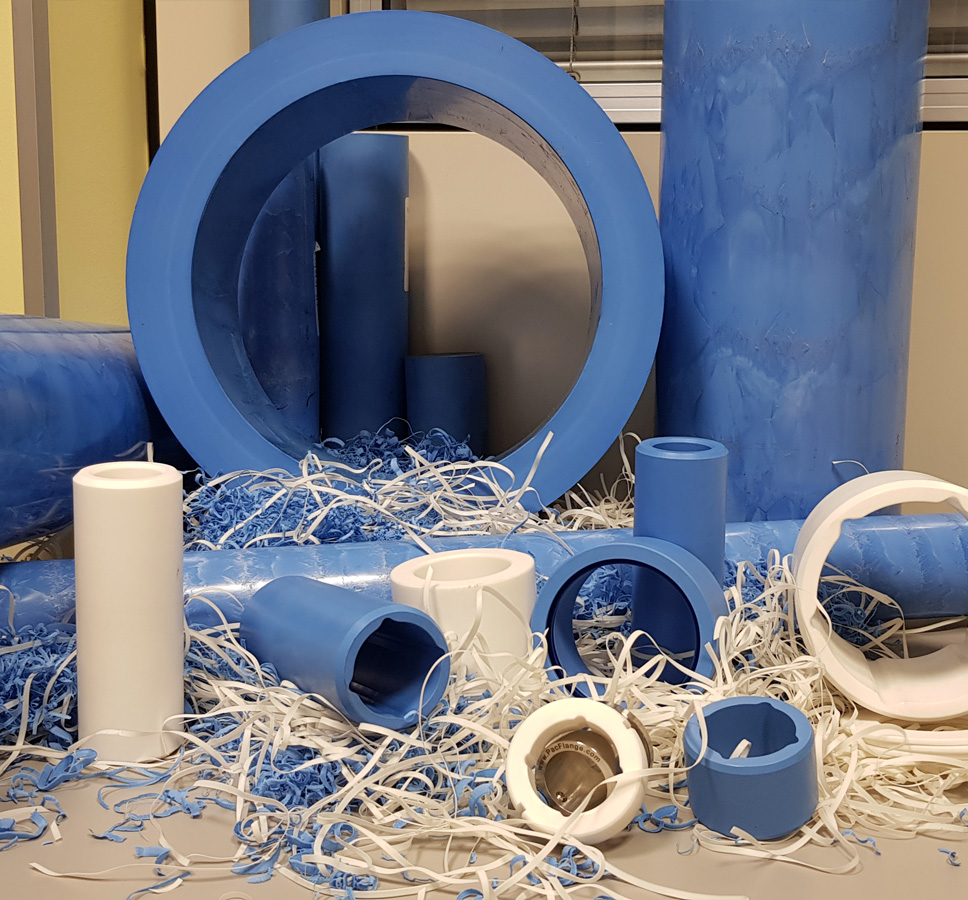

Thordon is a Canadian product developed and manufactured by Thordon Bearings Inc. in Burlington, Ontario. It was introduced to the Canadian market in 1966. Today it is sold through distributors in Canada, the USA and in more than 70 countries around the world.

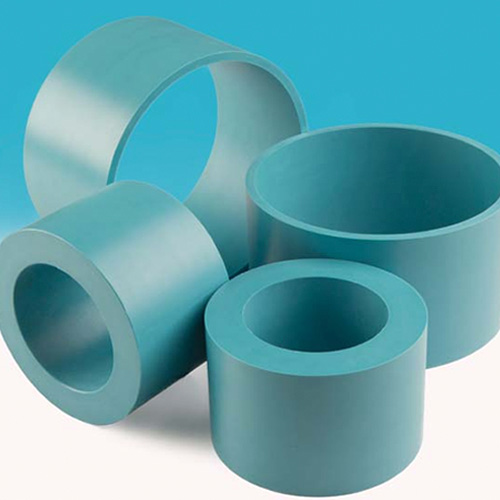

Thordon has different types/grades which offer specific operating advantages depending on the different applications. The different grades and types are:

This is a material manufactured by extrusion whose main characteristics are the ability to withstand high pressures and high temperatures, the low coefficient of friction and a very low liquid absorption. High chemical resistance.

The properties of thermoplastics include: